Research

Center for Structural Fire Engineering and Diagnostics

Background: Fire represents one of the most severe environmental hazards in the design and fabrication of civil (built infrastructure), mechanical, aerospace and nuclear structures. Unfortunately, the U.S. has one of the worst fire-loss records in the industrialized world, as demonstrated by the large number of deaths and property destruction. Further, a number of recent white papers and reports conclude that there is serious lack of understanding, test data, tools, technologies and qualified personnel to facilitate structural fire safety design. This was mainly attributed to the fact that within the area of fire science, structural fire safety is the least developed.

Presently, design for fire is based on prescriptive approaches, either through standard fire test data or simplified empirical methods. It is widely recognized that this traditional approach does not provide a realistic assessment of structural performance due to a number of serious drawbacks in the methods. There has been no improvement to these methods due to the lack of knowledge on fire characteristics, material properties at high temperatures, and validated simulation models. Hence, current fire protection codes and standards provisions do not account for the realistic response in actual fires and thus will not provide rational and cost-effective designs.

SAFE-D Center: To address the above illustrated fire problem a Center for Structural Fire Engineering and Diagnostics has been recently established though Strategic Partnership Grant Award by MSU Foundation. This center is led by Department of Civil and Environmental Engineering (CEE) and is in collaboration with Department of Mechanical Engineering and Department of Physics and Astronomy in College of Natural Sciences.

FEMA report stressing the need

R&D in Fire Engineering

Highway bridge Collapse in OakLand, CA due to fire

The Center will address fire issues related to the built environment (civil infrastructure) in the civil, mechanical, and transportation sectors. The research to be undertaken at the proposed center, will lead to the advancement of fire safety science, and will produce innovative fire resistant materials, high temperature sensors, engineering design tools and advanced degree holders who will perform fire resistant design and construction in multidisciplinary engineering applications. Currently efforts are underway to further expand the research activities through the establishment of a self-sustaining research and technology center in Structures Fire Engineering and Diagnostics area.

Fire Test Facilities

As part of this Center activity, state-of-the-art equipment is being set-up for undertaking fire experiments on materials and structural systems, critical for research in this interdisciplinary area. This includes structural fire testing furnace, the first of its kind in an American university, and various material characterization instruments for measuring at high temperature properties.

-

CEE has recently established structural fire test furnace for testing loaded structural assemblies (such as columns, beams and floor systems) under extreme fire conditions. The furnace is housed in a new addition, which has been completed recently, to the existing Civil and Infrastructure Laboratory building. The integrated heat furnace-loading system, dedicated in June 2007, was specially designed and built so that it could produce conditions to which a member might be exposed during a fire, such as fire temperatures, structural loads and heat transfer. It consists of a steel framework supported by four columns with the furnace chamber (fire exposed area) of about 8 x 10 ft. inside the framework. The furnace is equipped with six natural gas burners, and can simulate a temperature course consistent with the standard or realistic fire scenarios. Two small view ports on either side of the furnace wall provide for visual monitoring of the fire-exposed surface during tests. Figure 1 shows the test facility that has been installed at the CIL of MSU.

-

The material property instruments include, "thermal property measurement instruments” for thermal property measurements, a "cone calorimeter" to measure flammability, mass loss, and gas emissions, a "mechanical property measurement device" for measuring stress-strain response of materials, and "chemical composition measurement devices", for undertaking material characterization at high temperature.

Current Students/Projects: About dozen graduate students (8 PhD, 3 M.S. and 3 visiting scholars) are pursuing research in various fire related projects. Many of these projects are funded by federal agencies (NSF, NIST), Industry (NEx-ACI, AISC, PCA, PCI) and other sources (MSU Foundation).

Opportunities for Graduate Studies: Assistantships are available for students wishing to pursue graduate studies in structural fire engineering. Interested students should send in their complete applications to CEE department and should indicate in their applications their interest on pursuing dissertation in structural fire engineering field.

Recently Completed Research Projects

Fire Resistance of Steel Bridge Girders

-

Aziz, E, Kodur V.K.R., Glassman J, and Garlock M. M. E., “Behavior of steel bridge girders under fire conditions", J. of Constructional Steel Research, Vol. 106, 11-22, 2015.

-

M.Z. Naser, V.K.R. Kodur, Comparative fire behavior of composite girders under flexural and shear loading, Thin-Walled Structures, Volume 116, July 2017, Pages 82-90.

Center

A custom designed integrated small-scale load-furnace apparatus is being acquired through PI start-up funds for testing small specimens to measure stress-strain response and creep as a function of temperature. In addition, instruments such as Differential Scanning Calorimeter (DSC), Differential Thermal Analyzer (DTA), and Dilatometric Apparatus are being purchased for establishing various high temperature thermal properties.

CIL has recently established structural fire test furnace for testing loaded structural assemblies (such as columns, beams and floor systems) under extreme fire conditions. The furnace is housed in a new addition, which has been completed recently, to the existing CIL building. The furnace acquisition was instrumented through the PO and a specialized furnace manufacturer and the furnace was dedicated in June 2007. The integrated heat furnace-loading system was specially designed and built so that it could produce conditions to which a member might be exposed during a fire, such as fire temperatures, structural loads and heat transfer. It consists of a steel framework supported by four columns with the furnace chamber (fire exposed area) of about 8 x 10 ft. inside the framework. The furnace is equipped with six natural gas burners, each with a maximum capacity of 406 kW for a total of 2.5 MW and can simulate conventional (building) or hydrocarbon fire. Six thermocouples distributed throughout the test chamber monitor the furnace temperature during a fire test. This data is used by the control system to adjust fuel supply, and maintain a temperature course consistent with the standard or realistic fire scenarios. This two-way system maintains the furnace temperature along a desired curve. Two small view ports on either side of the furnace wall provide for visual monitoring of the fire-exposed surface during tests. Figure 1 shows the test facility that has been installed at the CIL of MSU.

Facilities for fabricating steel (or concrete) specimens, for material property tests are found in the Department of civil and environmental engineering, in its Civil Infrastructure Laboratory (CIL). The CIL has a 40 ft. x 60 ft. strong floor area, with 2 ft. x 2 ft. grid of 150 kip capacity tie-down points and a roof height of 30 ft. (high bay). A 20 kip capacity crane services the strong floor area that will be used for moving the specimens after fabrication. Some costs have been identified in the budget for materials and fabrication of columns and beams.

State-of-the-art hydraulic testing equipment for testing materials such as steel, concrete, FRP are part of the CIL equipment. Additionally, the CIL and MSU have several specialized material testing equipment including 50 and 200 kip universal testing machines, fracture toughness testing equipment and a state-of the art world-class composite materials laboratory facilities. The CIL has also a state-of-the-art data acquisition system with 128 channels for displacement transducers, pressure transducers, rotation transducers, strain gages, load cells, thermocouples, accelerometers and other instruments.

Key Researchers

-

Dr. Venkatesh Kodur, Department of Civil Environmental Engineering

-

Dr. Indrek Wichman, Department of Mechanical Engineering

-

Dr. Ruby Gosh, Department of Physics and Astronomy

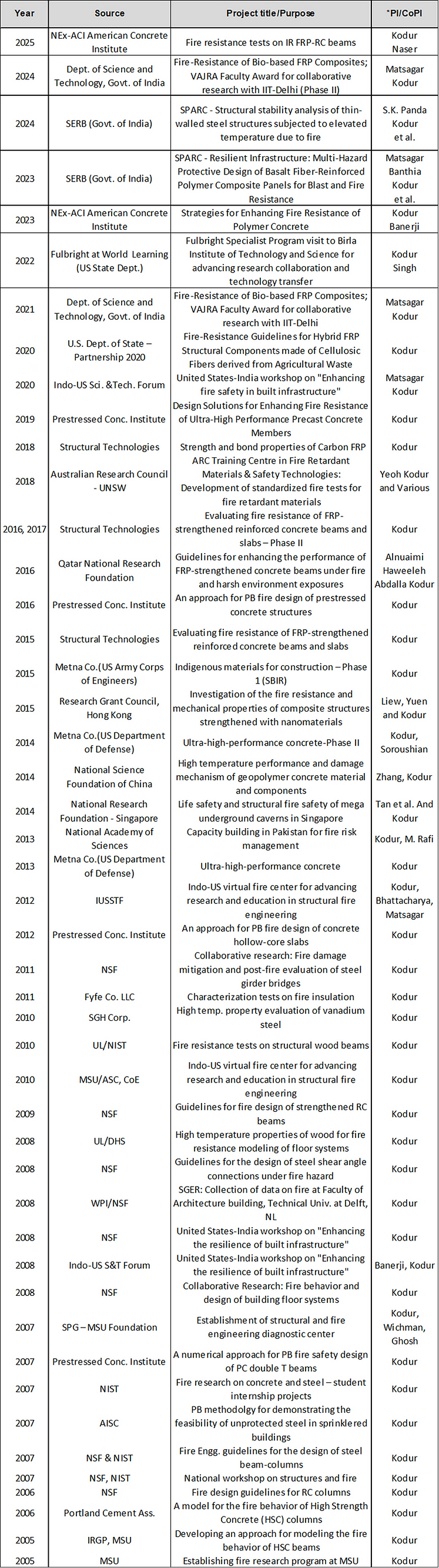

Research Projects

Pre-MSU Career